Tempo de espera :

60 daysPorto de embarque :

Xiamen portpagamento :

TT

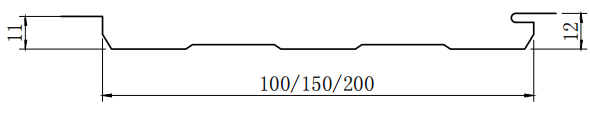

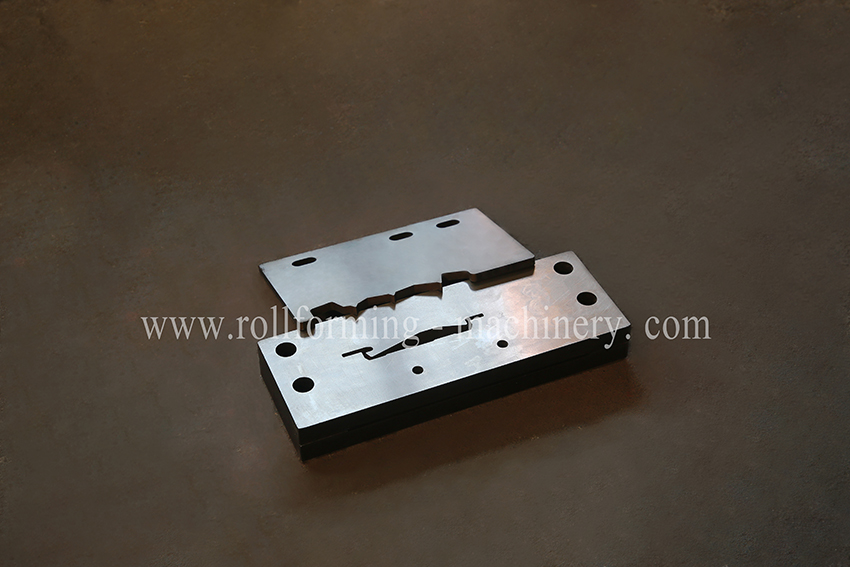

Effective Width: 248mm

Effective Width Tolerance:± 0.5mm

The Length Of Tolerance: ±1mm (6M)

Inspection Thickness: 0.6mm

Material Yield Strength: Q235-345Mpa

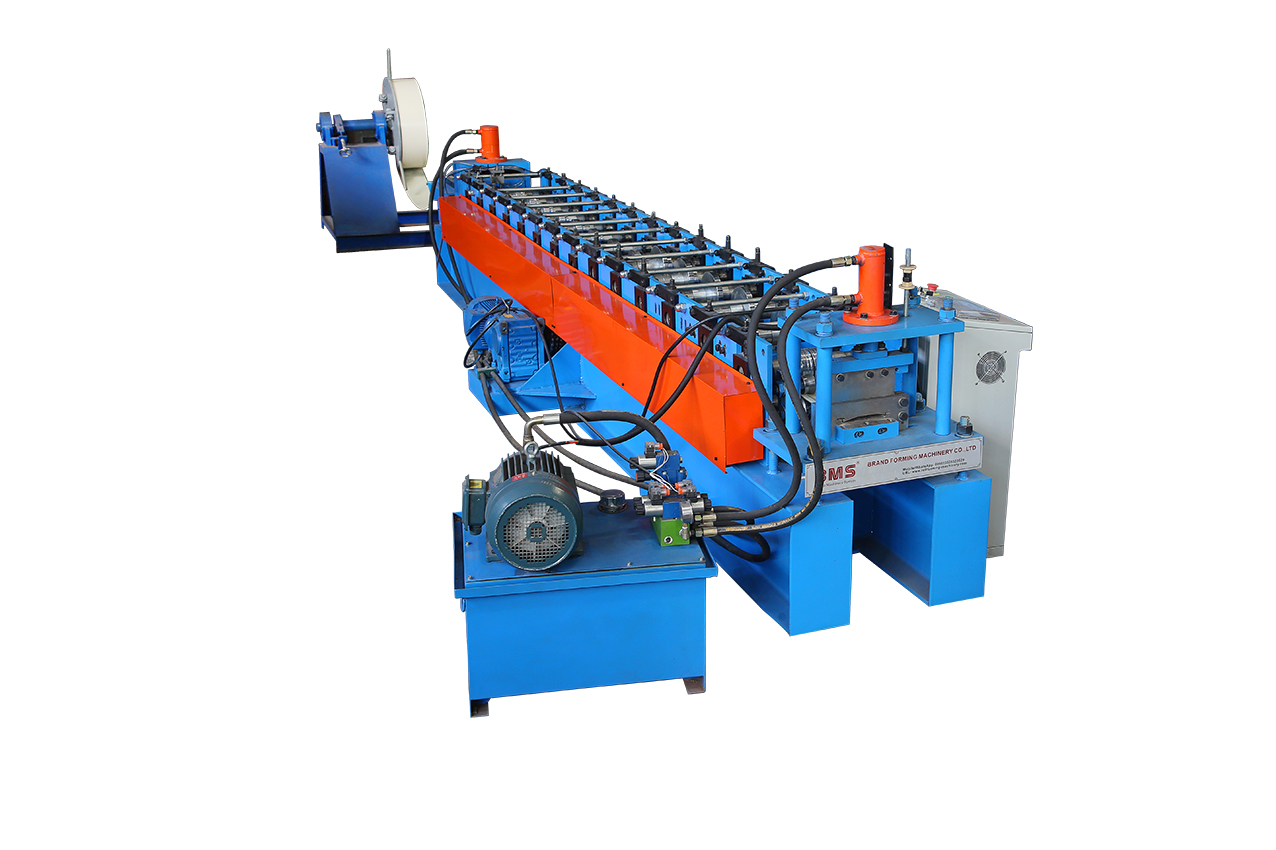

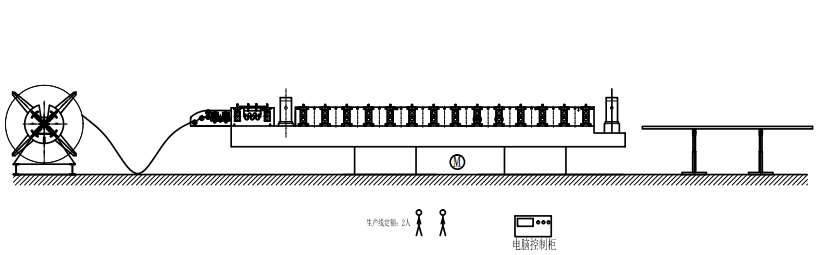

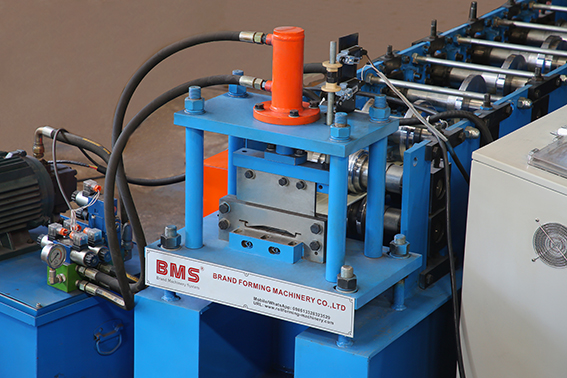

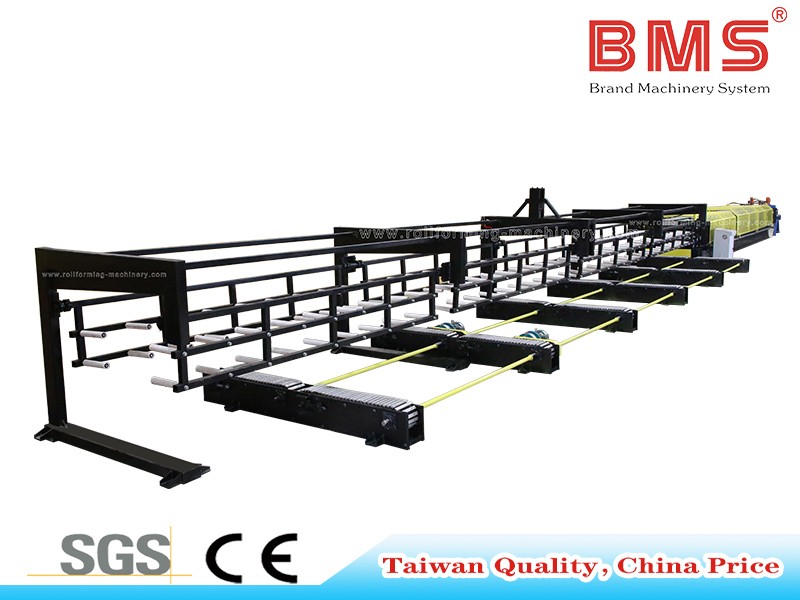

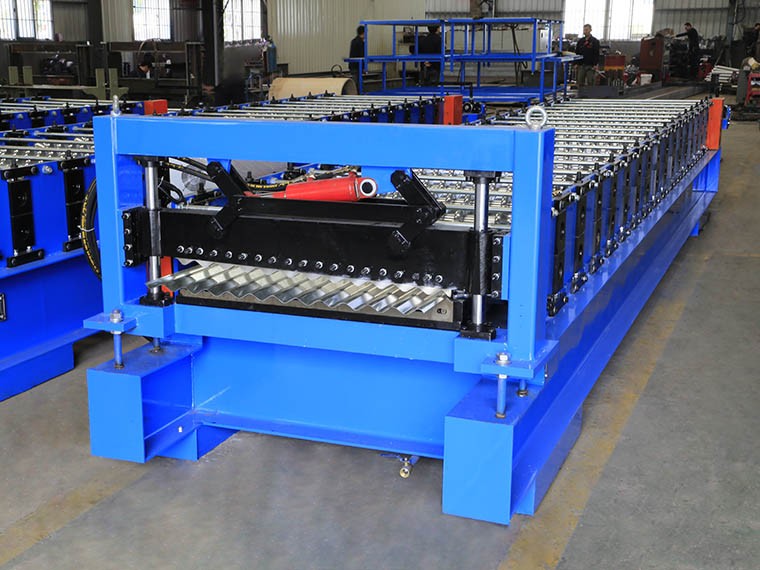

Uncoiler → Feed Guide Device → Hydraulic Punching Device → Roll Forming System → Hydraulic Post Cutting

Device → Exit Rack(3M)*1 → PLC Control System → Hydraulic Station

Manual/ Auto control steel coil inner bore shrinkage and stop

Max Feeding Width: 248mm

Max Capacity: 3ton

Body frame made from H400 type steel by welding

Side wall thickness: Q235 t18mm; Tie rod:ф65 Galvanized

Rollers manufactured from Bearing steel GCr12MoV(SKD11), precision machined, hard Chrome Coated; with thickness 0.5mm, surface with mirror treatment (for longer life and anti-rust); Shafts manufactured from 45# steel,Quenching and tempering heat treatment, hard chrome plating.

Gear & chain drive about 14-step to form

Main Motor= 5.5KW, Frequency speed control

Speed reducer motor: R series

Chain:ZIQIANG

All the screw bolts with grade 8.8 (cheap factories use low grade 4.8) to ensure fix the machine structure tightly and long life during the machine long time running.

Product speed: 10-15m/min (Including punching and cutting time)

Forming Speed:12-16m/min

Control the quantity and cutting length automatically

Input the production data (Production Batch, pcs, Length, etc.) on the touch screen ,

It can finish the production automatically.

Combined with: PLC, Inverter, Touch Screen, Encoder, Independent Cabinet type etc

The brand of hydraulic value: HUADE

The type of oil pump: Vane pump

Cylinder type/ brand: Welding Cylinder

Tank: External fuel tank

1. The warranty is 24 months after the client receives the machine.

Within the 24 months, we will courier the replacement parts to the client free of charge

2. We offer technical support for the entire life of our machines

3. We can send our technicians to install and train the workers in the clients' factories with extra cost

Main body of machine is naked and covered by plastic film (to protect of dust and corrosion), loaded into container

and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Dual Machine Para YX18-40 e YX35-38 Omega Profile (2 em 1), encontre detalhes completos sobre Dual Machine, Dual Machine- BMS Machinery

Learn More

Seamlock 760 Roof Panel Roll Forming Machine Which are mostly used in industrial base、factory buildings、a roof of private house and so on.

Learn More

Standing Seam Roll Forming Machine with Low price, light weight, recyclable, simple operation, low maintenance cost.

Learn More

Saving time and funds for our customers. High efficiency, high precision, high speed production. Long service life. Easy to operate.

Learn More

The latest roll forming machines and innovative roll forming systems have been our trademark for decades: with our roll forming technologies we are amongst the world’s market leaders. You benefit from our comprehensive know-how and our flexible roll forming concepts, which we develop and implement to exactly match your requirements.

Learn More

High Productivity & best after-sale service. High-end equipment. Experienced Team. State-of-the-art process. Excellent quality。

Learn More

Professional engineer to commissioning and training. 24 months guarantee. Metal Roll Forming Machine, customized design, competitive price. ISO9001 & CE Certified.

Learn More

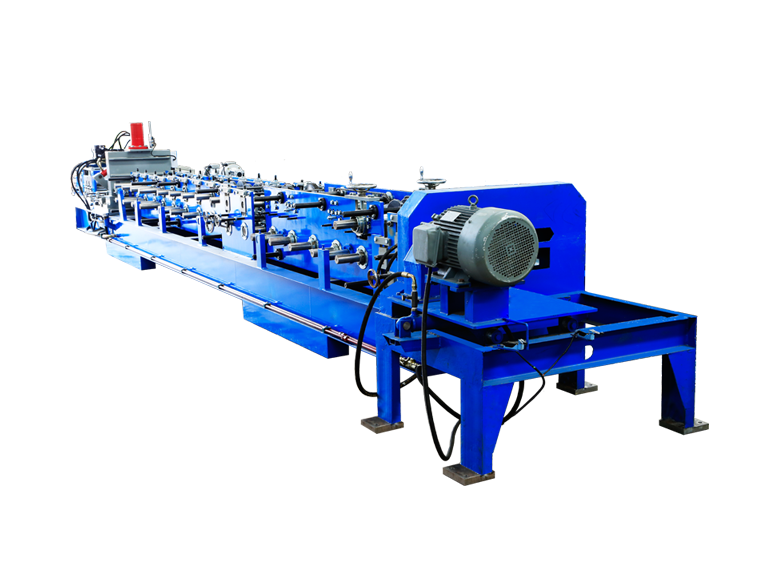

Focus On C Purlin Machine Exporting For 20Years, professional manufacturer in China. High quality standard. Efficiency & reilability. Factory price. welcome inquiry! Finest quality. Factory price. Quality Assured. High quality. Factory Direct Sales.

Learn More

Enhance your tile production with efficient corrugated panel roll forming machine available on BMS

Learn More

High efficiency, high precision, low production cost, long service life. Over 20 years focus on flexible roll forming. Saving time and funds for our customers.

Learn More

ISO 9001&CE Verified Downspout Roll Forming Machine, High performance, Competitive Pricing.

Learn More

5 Station Electric Seaming Machine: HOT SALES with Promotion Price USD 1000.00. Stock available for immediate shipment to worldwide.

Learn More

5 Station Electric Seamer for Metal Roofing: HOT SALES with Promotion Price USD 1000.00. Stock available for immediate shipment to worldwide.

Learn More

2 Station DI Roof Seamer Style Electric Roof Seamer: HOT SALES with Promotion Price USD 1990.00. Stock available for immediate shipment to worldwide.

Learn More

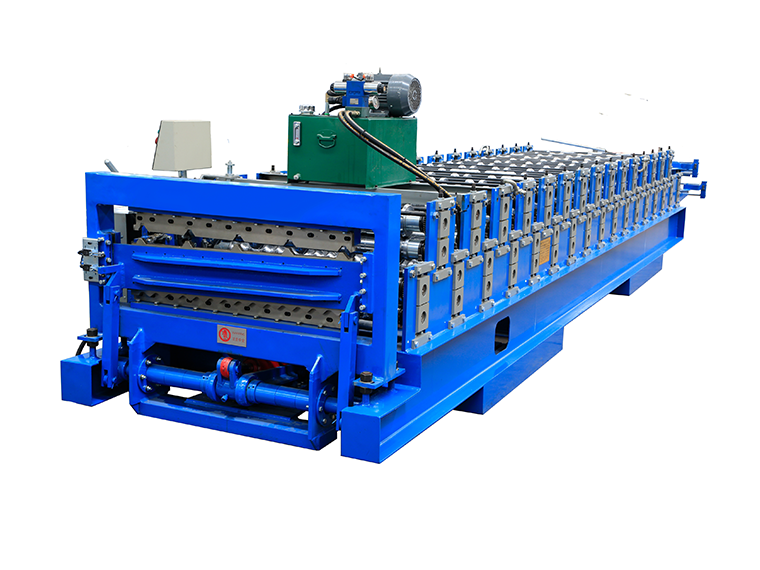

USA Type Double Layer Roofing Panel Roll Forming Machine With 12 Meter AUTO Stacker Device (Rib & PBR Profile)

Learn More

AUS Type Double Layer Roofing Panel Roll Forming Machine With 12 Meter AUTO Stacker Device

Learn More

American-style gutter forming machine, compared with bending machine, the forming machine is more efficient, and the forming R angle is beautiful

Learn More

Used as the floors of buildings because of low cost, light weight but high strength, short building period, and re-cycle use

Learn More

Used as the floors of buildings because of low cost, light weight but high strength, short building period, and re-cycle use

Learn More

low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength.

Learn More

Easy installation, short building period, beautiful appearance and is light weight but high strength.

Learn More

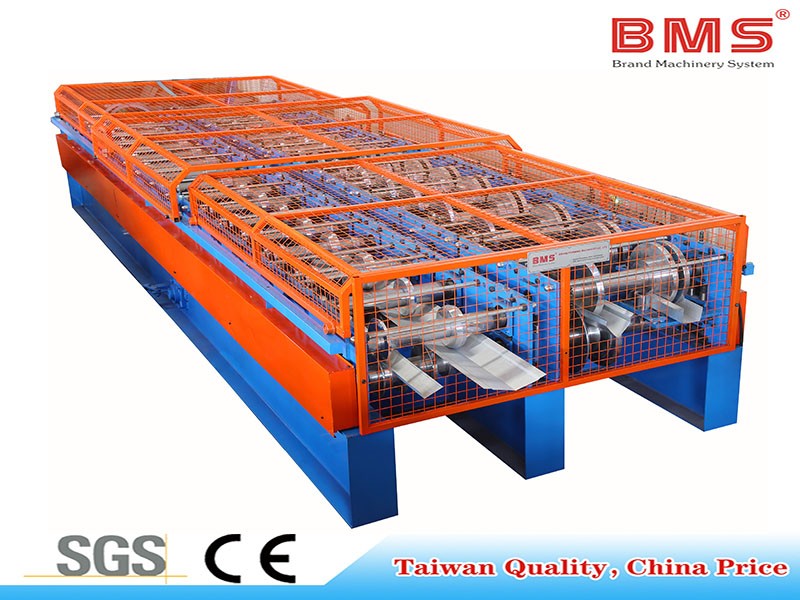

Different roof panel machines can produce different shapes of steel roof, wall sheets according to the clients' profile drawings and requirement. Steel roof, wall sheets are new building materials with various thickness and colors. They have many advantages, such as low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength. They are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers, etc.

Learn More

The complete corrugated roof panel machine line includes decoiler, main machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system. We simply program the pieces and length we need in the computer and the wave panel machine produces it automatically. The machines are easy to operate and running stable.

Learn More

Corrugated Panel Roll Forming Machine for South Amercian market(like Bolivia),with Taiwan Quality,China Price.

Learn More

Low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength.

Learn More

We manufacture wide range products of metal sheet cold roll forming machines as follows: purlin forming machine(including C Purlin roll forming machine, Z purlin rolling machine, CZ purline roll forming machine), floor deck roll forming machine, roofing machines (including roof tile making machine/roof tile forming machine

Learn More

The complete glazed tile forming machine line includes decoiler, main machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system. We simply program the pieces and length we need in the computer and the glazed tile forming machine produces it automatically. The machines are easy to operate and running stable.

Learn More

This Purlin Roll Forming Machine Can Produce different CU60-200 purlin size without changing rollers or spacers.

Learn More

Easy installation, short building period, beautiful appearance and is light weight but high strength.

Learn More

We produces different size of purlin roll forming machine without changing the rollers or gaskets.

Learn More

widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product.

Learn More

Easy installation, short building period, beautiful appearance and is light weight but high strength.

Learn More

Klip-Lok Roof Panel Roll Forming Machine is Beautiful appearance, light weight and high strength.

Learn More

Corrugated Steel Panel Roll Forming Machine to produce Taiwan Popular corrugated roofing panels or wall panels.

Learn More

The tile roof machine can produce various of tile panel, which are used to construct curvaceous roofs, It can substitute the traditional clayey tile and cement tile and save much land resources. And the raw material can be in different color, with elegant and noble looking.

Learn More

The purlin machine can produce size C50-150 It is widely used as the supporter of roof and wall in large-scale and mid-scale construction,.and our automatic C purlin machines can automatically replacement purlins’ model number.,have a high speed(20M/min). .

Learn More

The advantages of High Quality C Purlin Roll Forming Machine C50-200 when comparing with Traditional Purlin Machines are as follows: 1.Produce different purlin size without changing rollers or spacers. 2.No need changing cutter for different size. 3.Easy operation, low maintenance cost 4.Infinite sizing(any size within machine range),help to save material 5.Optional Punch hole at any position of purlin web side and flange side

Learn More

Incorporate the Taiwan latest features in steel stud and track manufacturing technology with advanced PLC control systemsile).

Learn More

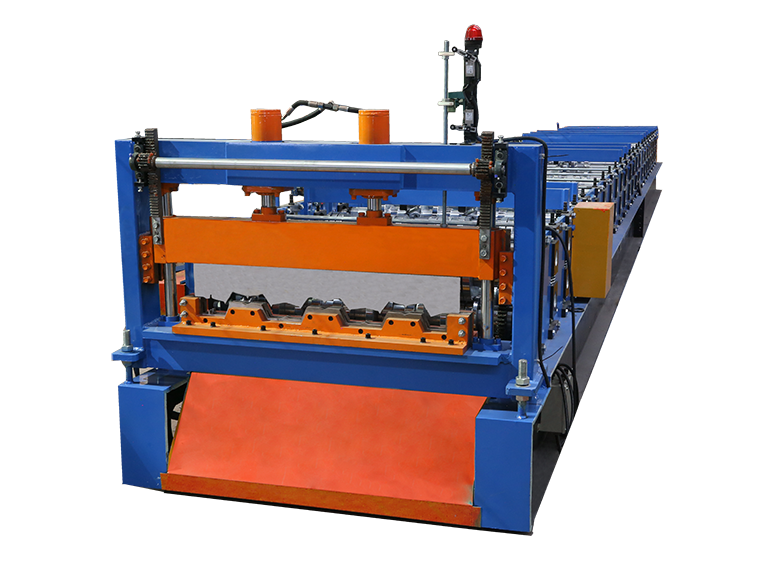

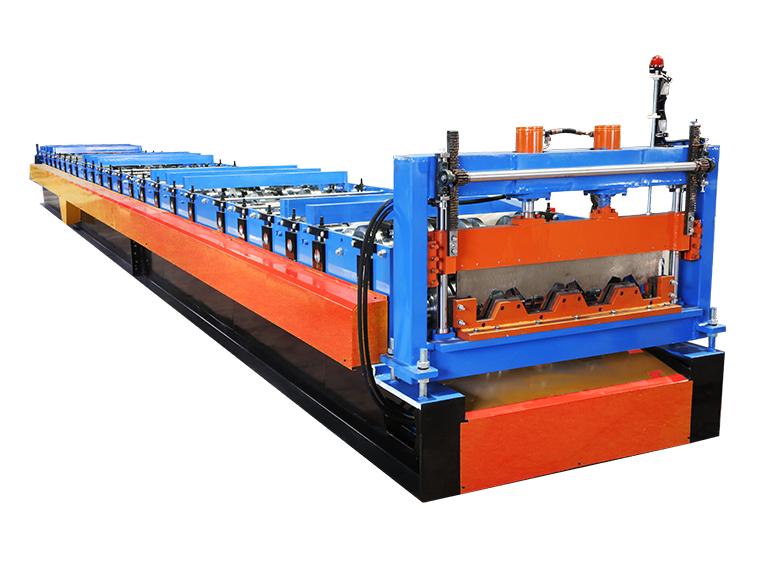

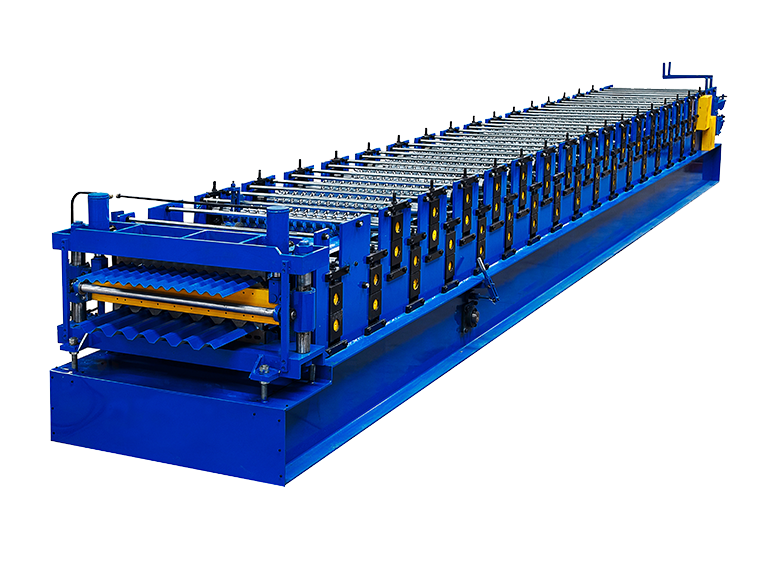

Double Layer Roll Forming Machine can roll form two different roofing profiles without changing anything because it has two layers. Upper and lower can rollform different profiles. Besides,the sea freight for import is saved by 50%.It is popular choice of both new entrepreneurs and established metal building manufacturers. The advantages of Quick Change type Purlin Roll Forming Machine when comparing with Traditional Channel Machines are as follows: 1.Produce different roof panel size in one machine 2.Save space 3.Easy operation, low maintenance cost

Learn More

Roll form two different roofing profiles without changing anything Besides,the sea freight for import is saved by 50%.It is popular choice of both new entrepreneurs and established metal building manufacturers.

Learn More

Double Layer Roll Forming Machine can roll form two different roofing profiles without changing anything because it has two layers. Upper and lower can rollform different profiles. Besides,the sea freight for import is saved by 50%.It is popular choice of both new entrepreneurs and established metal building manufacturers. The advantages of Full Automatic Double Layer Roll Forming Machine are as follows: 1.Produce different roof panel size in one machine 2.Easy operation, low maintenance cost 3.Save space

Learn More

The tile roof machine can produce various of tile panel, which are used to construct curvaceous roofs, It can substitute the traditional clayey tile and cement tile and save much land resources. And the raw material can be in different color, with elegant and noble looking.

Learn More

It incorporate the Taiwan latest features in steel stud and track manufacturing technology with advanced PLC control system. Applicable material: Galvanized steel(GI),prepainted galvanized steel(PPGI),SGCC,SGCH.Yield strength 245Mpa(commercial hard)~550Mpa(full hard, high tensile). The purlin machine can produce size C50-150 It is widely used as the supporter of roof and wall in large-scale and mid-scale construction,.and our automatic C purlin machines can automatically replacement purlins’ model number.,have a high speed(20M/min). .

Learn More

Automatic C75-300 purlin machine can produce different purlin size without changing rollers or spacers.

Learn More

Easy to operate and running stable,Kirby Style,popular in USA,Middle East&Africa,India and South East Asia

Learn More

Multi Profile Trim Roll Former: 1 machine to make 4 trims:Ridge Cap, Gable Trim,L Trim and Corner Trim.Or customized trims or flashings: J-Channel, Snow gaurd, Rake, FJ, V-Valley,W-Valley Eave Trim,Angle Trim, Drip Edge, Z-Trim / Z-BAR

Learn More

Standing Seam Roofing Roll Forming Machine can make 300/400/500/600/700 Width, KALZIP/LYSAGHT/BEMO/KINGSPAN Style available.

Learn More

Downspouts mainly collect roof rain water, which is part of the downspouts system, and concentrate on the rainwater pipes laid below the ground.

Learn More

A BMS Machine (anteriormente denominada BRAND FORMING MACHINERY CO., LTD, BMS é nossa marca de alta qualidade para o mercado de exportação) foi criada em 1996, membro do BMS Group, que cobre uma área de mais de 30.000 metros quadrados. Com mais de 20 anos de profissão...

Longchi Development Area,Zhangzhou Taiwanese Investment Zone,Fujian Province,China.

Longchi Development Area,Zhangzhou Taiwanese Investment Zone,Fujian Province,China. +16266453696

+16266453696 sales02@rollforming-machinery.com

sales02@rollforming-machinery.com